COVID-19 has created unprecedented challenges to our society. In the past months, we have realized the importance of relying on safe and reliable personal protective equipment for both the re-opening of our economy and the protection of our society. Face masks have become an essential accessory in our lives. The increasing demand, combined with a shortage of this protective gear, have pushed individuals and industries to look at alternatives, including artisan reusable masks and other equipment.

The available scientific evidence on the filtration performance and breathability of improvised materials used in artisan masks is limited, sometimes contradictory or have been designed without giving consideration to the particularities of the novel COVID-19 virus.

This project is funded by the Mitacs Accelerate program to allow the interns (Ph.D. student Nathalie Duponsel and MFA student Ryth Kesselring) to collaborate with IRSST and in a multidisciplinary environment to create face mask prototypes and evaluate their efficiency (particle penetration) and pressure drop (breathability). We are investigating two intersecting streams: (1) Mask Forms (including cloth masks, and 3D-printed mask devices), and (2) Filtration Materials.

This project builds on a unique collaboration between Concordia University’s Filtration Aerosol Laboratory (Ali Bahloul) and the Milieux Institute for Art, Culture and Technology (Barbara Layne and Ann-Louise Davidson) and the Institut de recherche Robert-Sauvé en santé et en sécurité du travail (IRSST), offering world-class facilities and unique equipment to perform the pioneering research demanded by this project.

The findings of this project will help in the fight against COVID-19 by providing insight and guidance to industry and community to 1) design and choose the most breathable materials to make face masks and 2) design face masks that reduce leakage, improve comfort. This is done through studying the effect of design on leakage using a manikin head and the effect of the material and sewing on filtration and breathability. Aside from providing our results to industry, we aim to mobilize knowledge to the public at large to help make better face masks at home.

Ongoing deliverables:

Making Better Fitting Facemasks With a Quick 3D Printed Frame:

https://www.instructables.com/Making-Better-Fitting-Facemasks-With-a-Quick-3D-Pr/

Chinese translation of the Instructables: https://vmaker.tw/archives/53008

CBC Let's Go (Nathalie Duponsel is interviewed by Sabrina Marandola) https://www.cbc.ca/listen/live-radio/1-383/clip/15857883

Global News: Concordia Students Find a Way to Make Surgical Masks More Effective https://globalnews.ca/news/8147193/concordia-students-surgical-masks/amp/

3D Cloth Facemask Design for Improved Fit and Comfort:

-

Ann-Louise DavidsonProfessor | Director of Innovation Lab

-

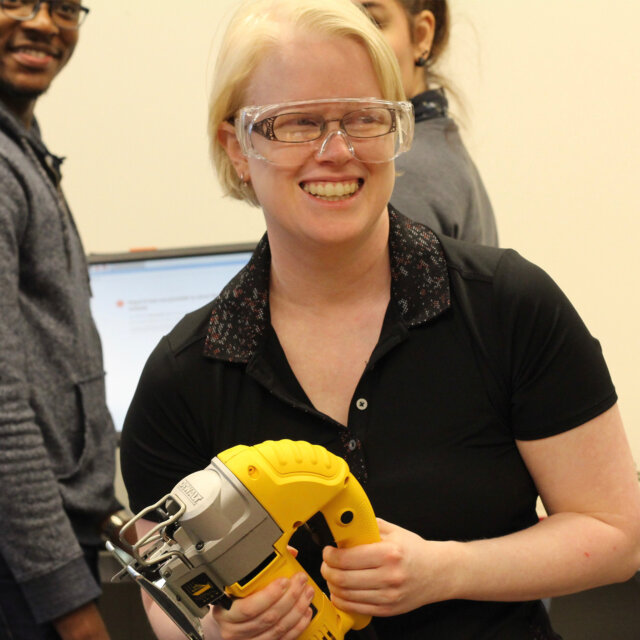

Nathalie DuponselPhD student in Education

-

Barbara LayneEmeritus Professor

Nathalie Duponsel

Professor Emeritus Barbara Layne is the Director of Studio subTela and Co-Director of the Textiles and Materiality Cluster at the Milieux Institute for Art, Culture and Technology at Concordia University. Layne lectures and exhibits internationally, most recently in AS-Helix: The Integration of Art and Science in the Age of Artificial Intelligence Exhibition at The National Museum of China, Beijing, the Festival de la Image Exhibition, Museo de Arte de Caldas, Manizales, Colombia and Taking Care, Ars Electronica Exhibition in Linz, Austria. Her work is supported by the Canadian Foundation for Innovation, the Social Science and Humanities Research Council, the Conseil des arts et des lettres du Quebec, Hexagram and the Milieux Institute.